Workplace Safety at Sunset Hill Stoneware

Outside of being America’s Cleanest, Greenest Pottery, Sunset Hill Stoneware is also one of the safest potteries in its industry. We care about workplace safety, and it shows. Taking a look at our shop, you’ll find that none of our employees have to wear dust masks or respirators, plus the building is well-lit and designed for the ergonomic comfort of our staff.

Why is Sunset Hill Stoneware different though? Pottery is a dirty industry, with potters at a much higher risk of developing lung diseases over their careers. Sunset Hill Stoneware doesn’t want to put its employees in danger, so we take different steps to protect them. Some of these innovations are more visible than others—let’s take a tour through the shop to see them up close.

Custom Technology at Sunset Hill

Sunset Hill Stoneware’s co-owner, Duane Dunsirn, is a mad scientist. Over the course of his storied career, Duane has invented countless machines that we now take for granted. That includes the 14-color inline printing press and machinery to make coupons and stickers. His inventions even led to the creation of the McDonald’s Monopoly game. That’s not all though.

Duane invented what we call the BAS. It’s an automated climate control system that lets us monitor and maintain the temperature, humidity and ventilation systems both remotely and within the shop.

Environmental safety is important to us. To improve our environmental efforts, Duane developed a system to capture the heat from our kilns and reuse it to keep the shop warm without putting extra exhaust into the air.

At our production facility, his custom technology is in every inch of the shop. It protects our potters while they’re at work, all while reducing our carbon footprint. Nearly every station in our shop has mechanisms to trap dust as it becomes airborne, before it can reach our employees.

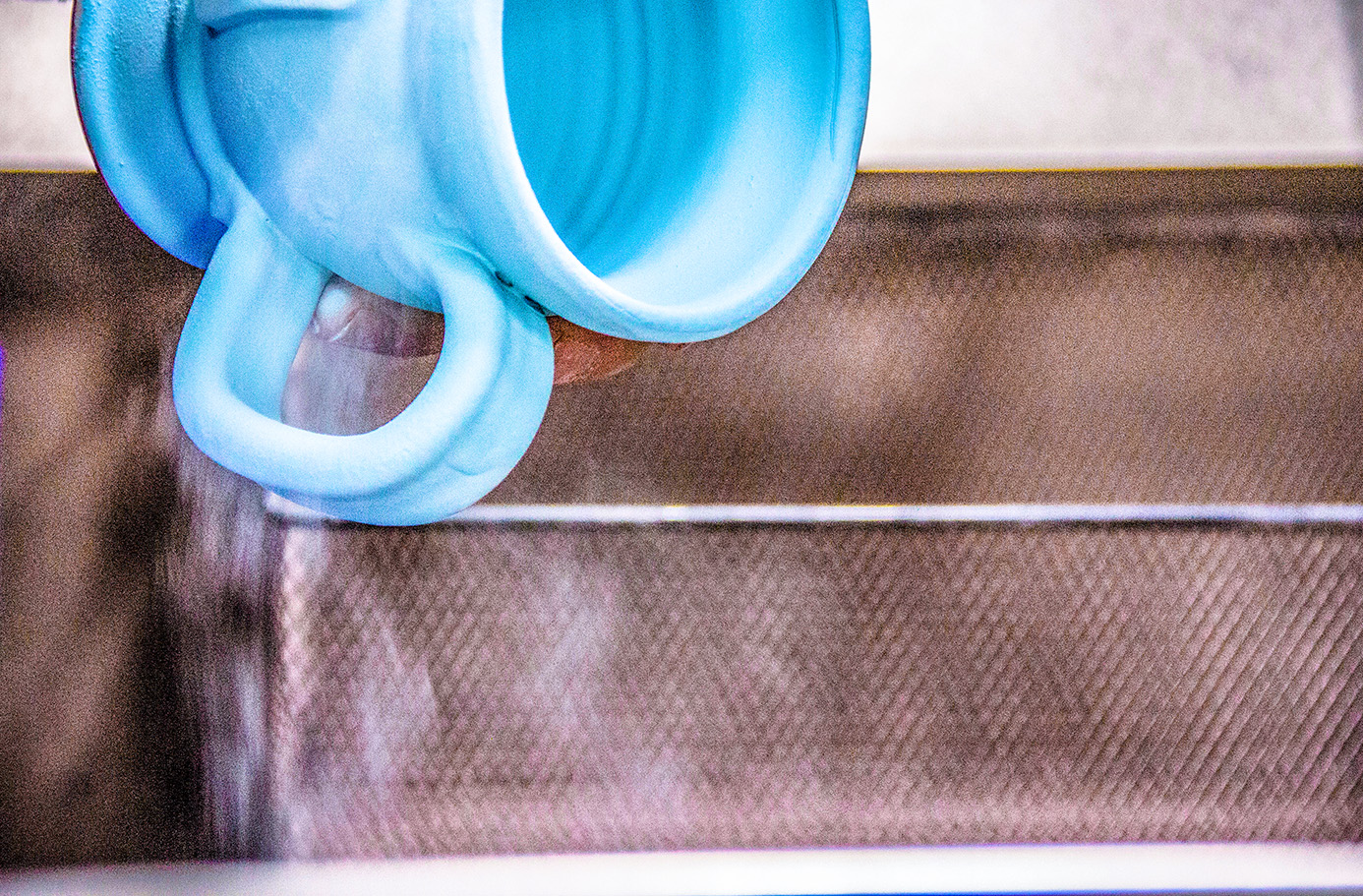

This system runs all through the facility, storing the dust in a filter so we can get rid of it on a regular basis. It takes dust both from the air and as wet clay left from our pottery wheels. We rinse the dust away under the floor, where we can filter it out before it enters the water supply.

We can credit so many of the safety and ergonomic features in our shop to Duane. Whether it’s as complex as our custom HVAC technology or something as simple as a raised storage station for clay so our team doesn’t have to bend as far to pick up clay, he’s designed most of the custom features of our shop with health and safety in mind.

Hidden Safety Measures

Some of our safety features are commonplace in just about any work environment. We have emergency evacuation routes posted in the shop so our team knows where to go in emergencies, where the first aid station is and where to shut off the water and gas mains. We also have signs displayed for our eyewash station and dangerous equipment. Where applicable, we also have protective eyewear that our employees must use while sanding the bottoms of our mugs.

However, plenty of the features designed to protect our employees and visitors aren’t visible with a tour of the shop. Instead it takes a more detailed look under the hood and in the pipes.

Kilns are infamously dangerous and need to be treated with respect. There are plenty of graphic stories of burns or injuries from hot kilns to prove this fact. Capable of reaching temperatures over 2000 degrees, it’s dangerous to be around a kiln in production, let alone touch it. That’s why we usually run the kilns overnight, so there won’t be anyone around them while they’re in operation.

That’s also why have a system to lock our kilns so nobody tries to use one that’s out for maintenance. It just involves some padlocks and a sign-in sheet, but it prevents any of our team members from using a kiln that’s damaged or dangerous.

Although we trap our heat, we don’t like to leave anything to chance in our firehouse. To reduce the risk of overheating in our kiln room, its doors automatically open after exceeding 120° F. From there, our team would have to close the doors after the area cools off enough.

Employee Stewardship

There’s a human element to our workplace safety efforts, too. Although our shop is designed to protect our team, each member of that team does their part to keep everyone safe.

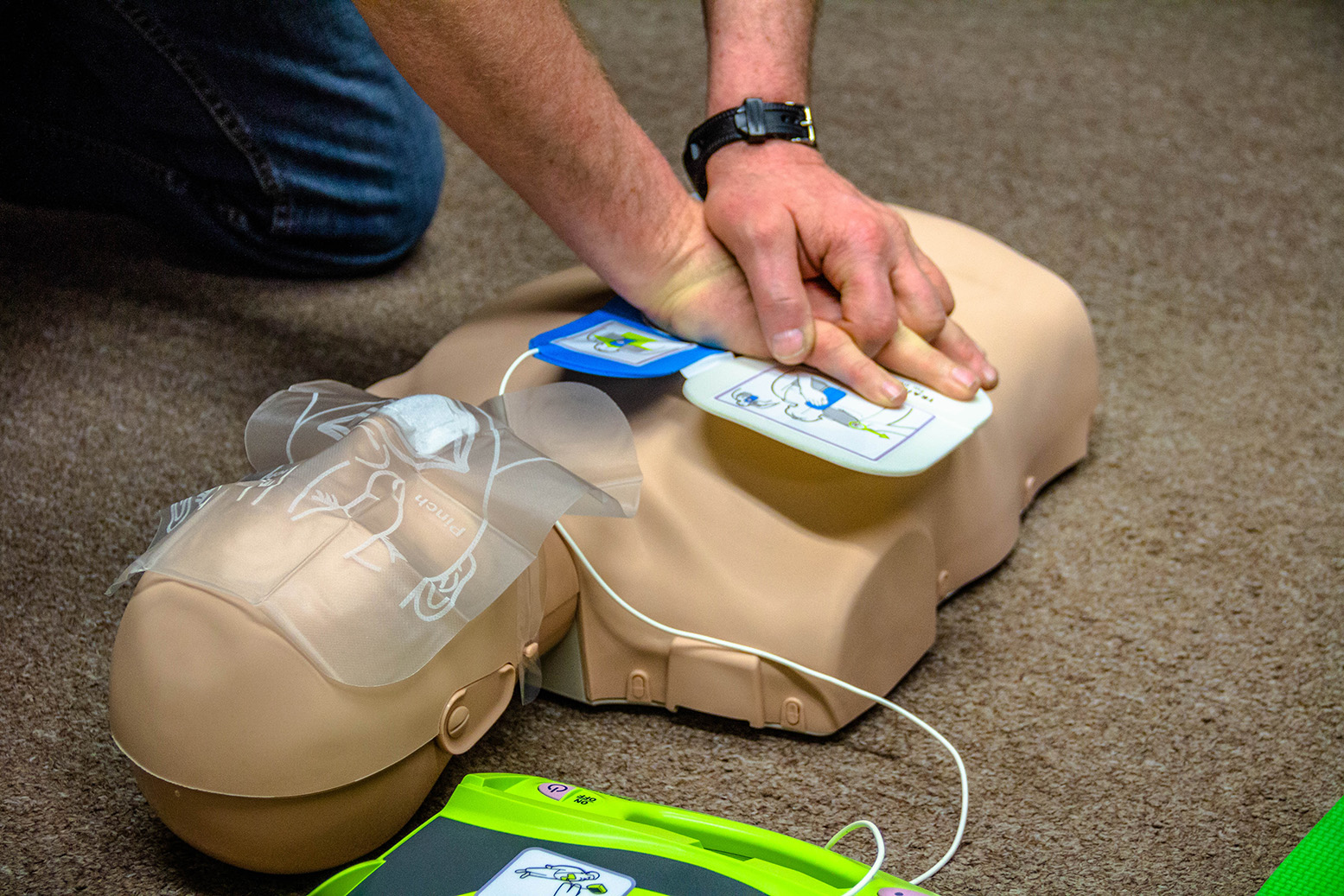

Additionally, Sunset Hill Stoneware has taken a few extra steps to train our employees on safety. Last month, we hosted a CPR and AED training course for employees at the shop, with seven of our team leads earning certifications. While we hope nobody in our shop ever has to perform CPR, use AED or use any of this emergency training, we feel better knowing we have seven people trained if the situation arises.

Beyond the realm of emergency situations, our shop team also goes through safety training on a quarterly basis. Provided by Fox Valley Safety in compliance with OSHA standards, these training programs cover topics across the board to promote safe and healthy practices in our shop and office, including protecting the joints and back, first aid safety, maintenance safety and more.

When it comes to safety, every step counts. Sunset Hill Stoneware uses safety innovations so you can have peace of mind that your mugs come from an ethically and environmentally friendly facility. We’re proud to have these innovations, and we will continue to develop them as our company grows.

[…] mentioned previously, we care about keeping our employees safe. One of the key ways we do that is with custom filtration […]